Small electric motors play an indispensable role in our daily lives, powering an array of household appliances, tools, and advanced technologies, including modern vehicles. These compact machines are often overlooked; however, their collective energy consumption can contribute significantly to overall efficiency improvements, especially when optimized. Researchers at Graz University of Technology (TU Graz) have recently made substantial strides in this field. Under the leadership of Annette Mütze from the Electric Drives and Power Electronic Systems Institute, the team embarked on an innovative project to maximize the efficiency of brushless drives used primarily in fan and pump applications.

With energy efficiency becoming an ever-pressing concern, especially in the sphere of renewable resources, exploring the potential of small electric motors is critical. While each motor functions independently and consumes minimal energy, when magnified by their widespread presence in various technologies, their energy savings potential becomes clear.

The research team at TU Graz has harnessed state-of-the-art design principles and control technologies to develop brushless integrated drives that not only use energy more sparingly but also contribute to quieter operations and reduced weight. One of the standout innovations involves the enhancement of claw pole motors, which are conventionally utilized for vehicle lighting. Although their application as diminutive drive units is less recognized, Mütze’s team has ingeniously addressed one of the essential drawbacks of these motors—cogging torque.

By manipulating the design of the claws through a process known as skewing and slotting, the team managed to mitigate cogging torque without incurring additional costs. The result is a reduction in the jerky engagement of the claws, which leads to diminished vibrations during operation. Mütze proudly reports a remarkable 70% decrease in one of the primary noise sources associated with these small drives, allowing for smoother and more silent motor functionality. This innovation signifies a leap towards noise reduction technology, potentially improving user experiences across various applications.

Another critical advancement unveiled by the TU Graz research team is in the regulation of current flow. Traditionally, pulse width modulation (PWM) has been the standard method for regulating motor speed; however, it requires numerous switching operations, which can lead to undesirable energy losses. Mütze’s team has drastically simplified this process. Instead of repetitively switching the power on and off, they implemented a more effective single-switch approach for each desired output rectangle. This innovation significantly diminishes the energy consumed during switching and ultimately leads to enhanced overall efficiency, particularly at lower currents.

The strategic reduction of switching operations also has financial implications. With fewer requirements for capacitors on the motor’s circuit boards, production costs can be lowered. In an age where economic considerations are as crucial as technological advancements, such reductions can drive mass adoption of efficient motor technology in various sectors.

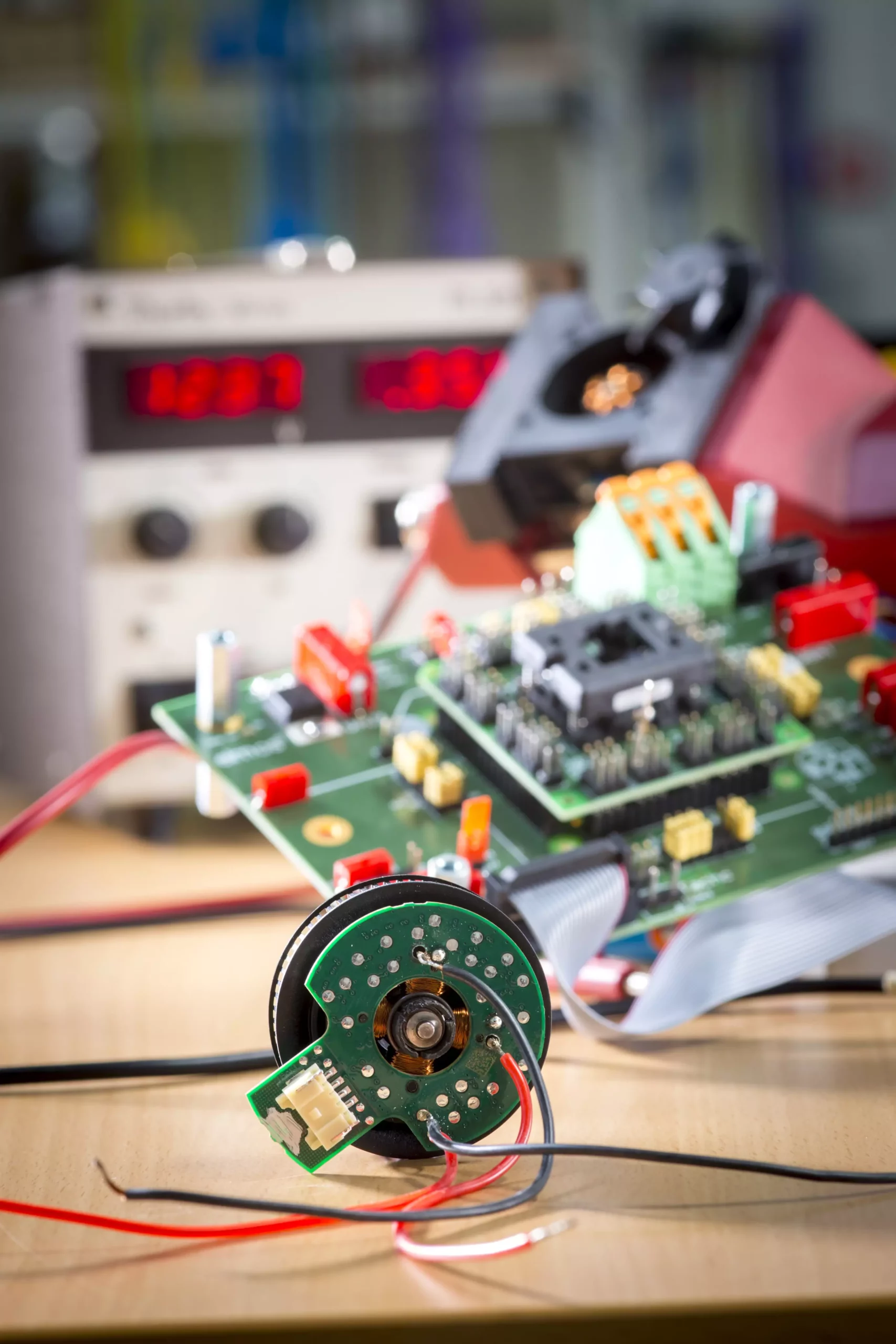

The implementation of PCB motors featuring ferrite cores stands as the crowning achievement of Mütze’s research. By designing the windings required for magnetic field generation as printed circuit boards, the manufacturing process incurs a higher degree of automation, benefitting from enhanced efficiency and precision. The integration of 3D-printed ferrite cores further optimizes the magnetic flux guidance, paving the way for the use of more affordable ferrite-based magnets.

The ability to make such cost-effective modifications without compromising performance is particularly relevant in an era where sustainable practices and resource efficiency are paramount. These technological advances could redefine the capabilities of small electric motors, potentially allowing for broader applications in environments that demand a smaller carbon footprint while maintaining high performance levels.

As the demand for more efficient and environmentally friendly technologies continues to escalate, innovations in small electric motor design will be essential. The research conducted by Annette Mütze’s team at TU Graz is pioneering a pathway towards improved energy efficiency, reduced noise levels, and lower production costs. As these developments ripple through various industries—ranging from household appliances to automotive systems—the future of small electric motors promises significant advancements that stand to benefit both consumers and the environment. The culmination of innovative design, advanced materials, and smart control mechanisms will not only transform motor applications but also contribute positively to global energy consumption trends.

Leave a Reply