In a significant advancement for structural engineering, a recent study published in the journal Engineering has introduced an innovative stress-strain model specifically designed for ultra-high-performance concrete (UHPC) confined by fiber-reinforced polymers (FRP). This pioneering research conducted by a team led by S.S. Zhang from Huazhong University of Science and Technology addresses a crucial knowledge gap in the behavior of UHPC when utilized in modern construction. With construction increasingly leaning on materials that promise superior strength and longevity, this study emerges at a pivotal moment, bringing fresh insights into the complexities of material behavior under confinement.

UHPC is distinguished by its remarkable mechanical properties, including high compressive strength and exceptional durability, making it a favored choice in modern infrastructure projects. However, the behaviors exhibited by UHPC when confined by FRP materials have puzzled engineers for years. While traditional models have adequately described the stress-strain relationships for normal-strength concrete (NSC) under similar conditions, these models do not effectively translate to UHPC, necessitating the need for a specialized approach.

Exploration of the Research Findings

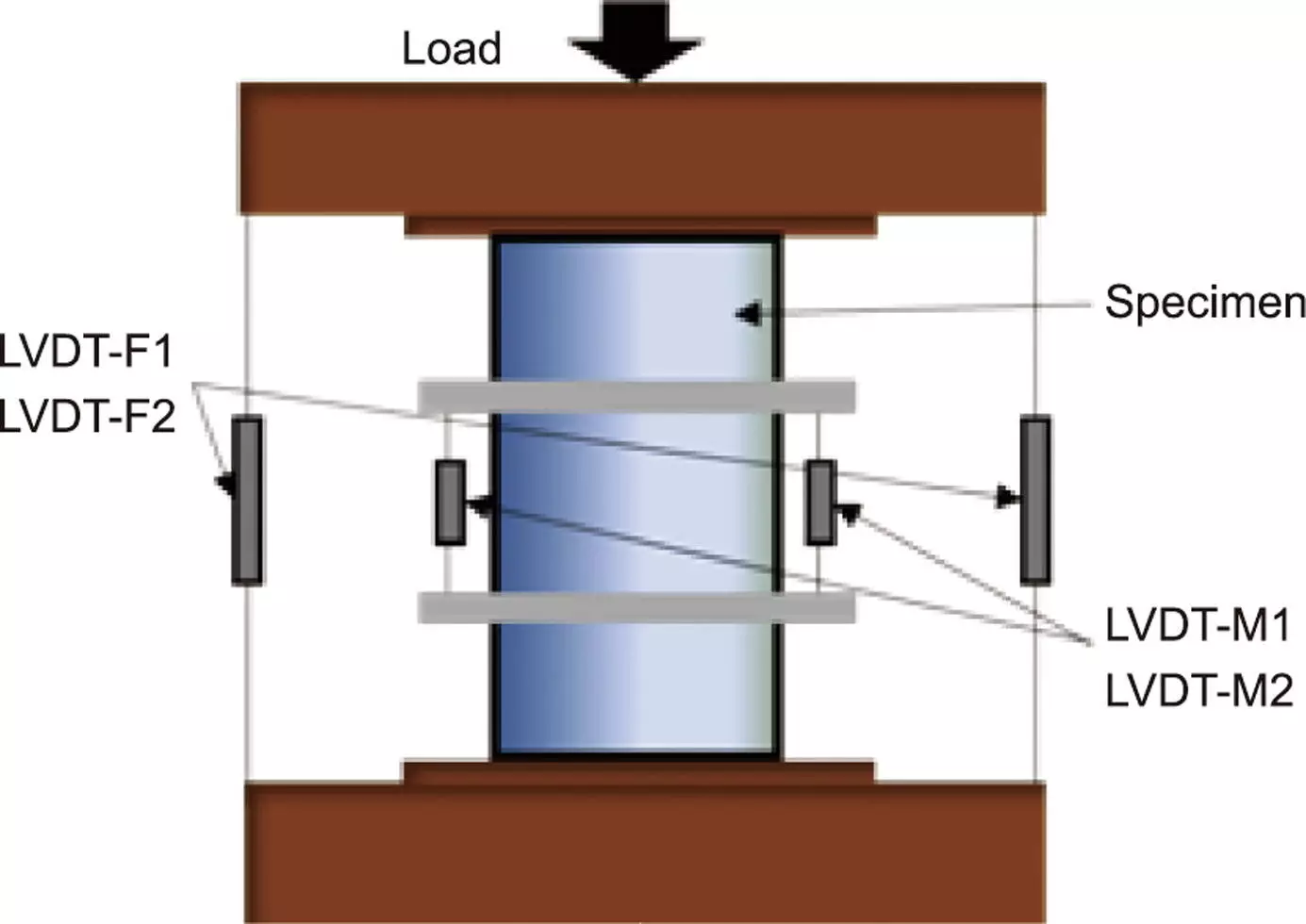

The study conducted by Zhang and his colleagues not only analyzed the compressive behavior of UHPC but also delved into the failure mechanisms that arise from concentric compression scenarios involving FRP. They executed a series of rigorous experiments to evaluate UHPC’s response, revealing that assumptions typically applicable to NSC, such as stress-path-independency, are inadequately reflective of UHPC’s complexities. This revelation was paramount; it motivated the research team to critically evaluate existing methodologies and to foster the development of a new model that accurately encapsulates UHPC’s response to confinement.

A notable finding of this research was the observation that major diagonal cracking in FRP-confined UHPC led to non-uniform lateral expansion, which severely affects the effective lateral confinement pressure. This understanding differs radically from traditional concrete behaviors, where uniform confinement is often assumed. As engineers, acknowledging this distinction is crucial, as it challenges the foundational assumptions laid out in prior concrete assessments.

Introduction of the New Analysis-Oriented Model

In response to these discoveries, the research team proposed a refined analysis-oriented model that embraces stress-path dependency, a concept previously overlooked in conventional models. By introducing a fresh equation that predicts the confining pressure gap, the researchers adeptly adjusted their analytical framework to offer a more accurate representation of FRP-confined UHPC responses. Rigorous validation against a substantial array of test results confirmed that this new model not only enhances predictive accuracy but also outstrips previous attempts.

The implications of this breakthrough are profound and far-reaching for the construction industry. With a reliable model in hand, engineers can now design structures utilizing UHPC with greater precision, thereby improving both the safety and performance of constructions. The research sheds light on potential future innovations as the industry increasingly demands more efficient and resilient materials to withstand the challenges of modern engineering.

This model empowers engineers and researchers with a robust toolkit capable of navigating the complexities of UHPC structures, enabling an era of inventive designs that prioritize strength, durability, and safety.

The advent of this analysis-oriented model represents a crucial development in the realm of concrete research and structural engineering. By bridging the knowledge gap that existed in understanding the stress-strain relationships of UHPC confined by FRP, this study elevates the dialogue surrounding high-performance concrete applications. As paving the way for innovative approaches to construction, motivation is now set for future studies to explore other materials and configurations within this realm, ensuring ongoing improvement in the safety and efficacy of structural designs.

This research ultimately serves as a beacon for engineers, guiding them towards optimized performance in UHPC applications, and inspiring confidence in the infrastructure that holds our modern world together. As we embrace these advancements, the potential for transformative changes in construction practices is substantial, ushering in a new era of high-performance concrete engineering.

Leave a Reply